I did not post any updates for a long time. I spent some time making some money with 3D printing to recover some of the costs from this hobby.

Unfortunately this turned out to be way more effort to comply with all laws and regulations for commercial sellers/makers. There wasn`t much to to blog about anyway. Apart from some modifications on the Voron 2.4 and a still half finished Voron 0.1, all my printers still run and run and need just little maintenance.

But I have a another problem that requires my 3D design/printing skills. We have 3 cats, one of the is quite old and has health issues. He has problems to get into a litter box with high walls and in the one we currently use, he frequently makes his business over the edge of the litter box, when he thinks he does not have enough space to full enter the box.

I also find it quite annoying to clean the litter box constantly, 3 big cats make a lot of mess. So I tried a couple of "self cleaning litter boxes". No matter if you spent just a couple hundred or over a thousand bucks, they all suck. Nearly all of them are small and all of them stop working after a while. I tried to hack a couple of them and tried my best to improve them. But after a while I just had to give up as the problems hit a point where it was unsustainable to waste more money and effort trying to fix them.

So I searched the Internet for DIY solutions for a self cleaning litter box. And I found a video from Micheal Bode https://www.youtube.com/watch?v=otlP7usU7jw , but with no further information on his project. I liked the size, yes it is big, and the ideas with the sensors. What I did not like to much was the fact he build it from wood and my fear war that the wood will soak in cat piss and smell awful soon. But in his description he linked the video that inspired him, from "haha ha" https://www.youtube.com/watch?v=xgOvI7tDEzc&t=0s . I liked it much more as he use plastic as material. But I already saw the flaw in his design. It is smaller and contains just less cat litter that then tend to stick to the walls.

But hey I am a 3D printing guy. So I searched the usual sites with STL`s for solutions. So I stumbled across a design from Thomas Krichbaumer https://cults3d.com/en/3d-model/home/self-cleaning-cat-toilett that also had a video in the description https://www.youtube.com/watch?v=wm88JU7OQdY&t=2s . His design also gave me some inspiration, but was not suitable for me as well. First our old cat would have problems to get in and would have to design something around it anyway. Second I was not sure about the size, if it is not to small either. So I decided to build my own.

My goals for the design where:

* It has to be big to give the cats enough room and hold a sufficient amount of cat litter. I settled with a drum diameter of 80cm and a depth of 50 cm. That was the perfect size for the spot where the current litter box is.

* It should be printable on a common printer like the Prusa MK3 and not require a huge printer. So the size of the parts was limited around 200mm for each side.

* There should be no need for a lot of supports as this project already used a lot of material.

* I wanted to use pins and screws to give it more stability. But also planned to glue it all together to be waterproof (or cat piss), once the design has worked out.

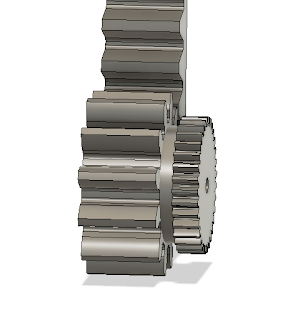

So I started out to design the drum first and this is what I came up with: