Over the last days everybody was excited about the MK3S and MMU2S announcement from Prusa.

I took the time and looked into it deeper. And I am not amused!

So let's start with the extruder upgrade. Prusa replaced the filament sensor with a new one to overcome the issues with the MMU2 and some filament types/colors. But before I start mocking about the new MK3S sensor, let me explain how the old Mk3 version worked.

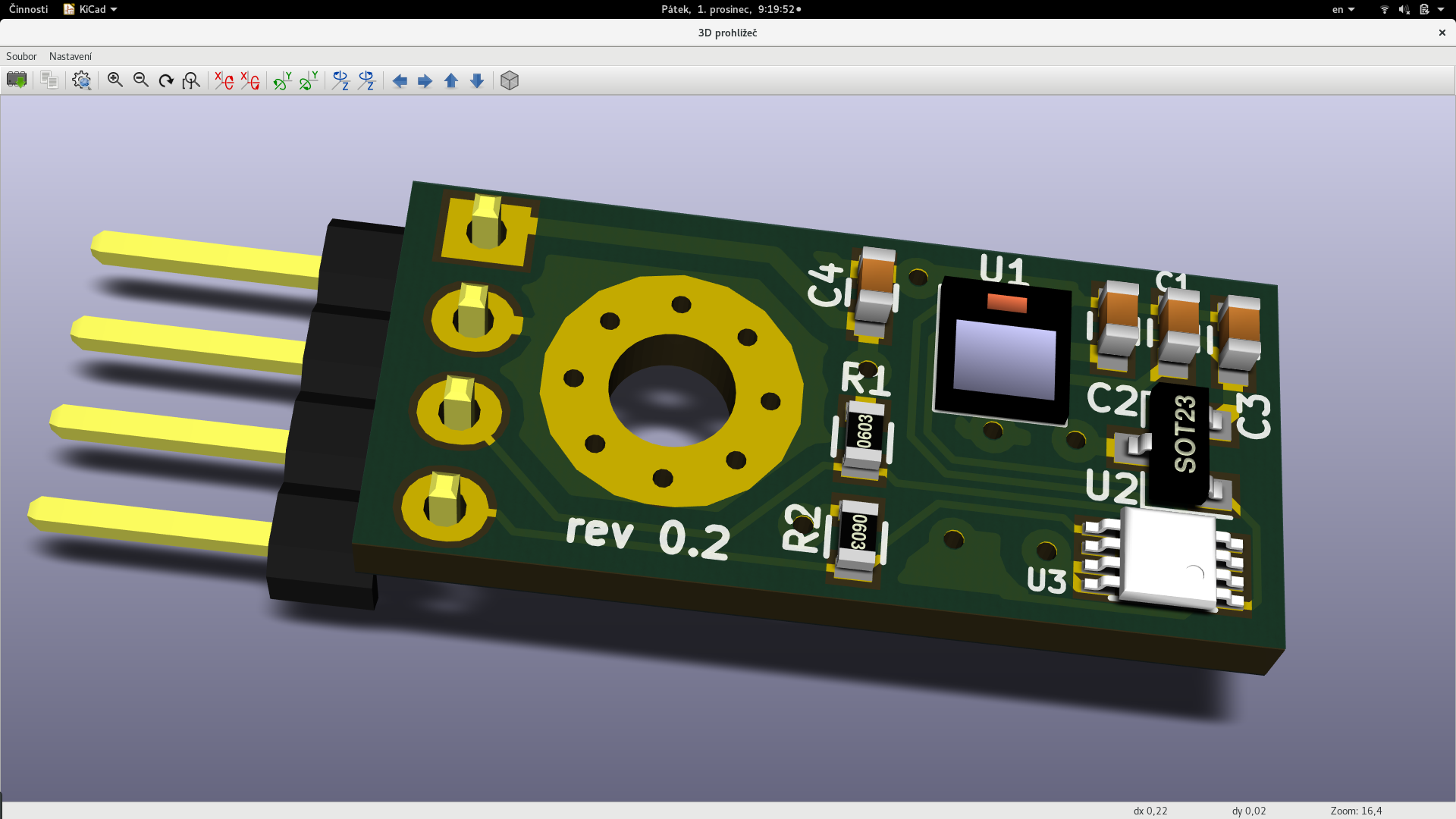

Prusa had developed an optical sensor that worked similar to an optical computer mouse. It could detect if filament was loaded, but also if the filament was moving. The PAT9125EL optical laser movement sensor had some issues with some types of filament and different colors. That led to false alarms for some users.

It seems like the tiny strings end the end of filament that can occur during the unload of filament increased the problems even further. Usually you just cut them off, but if you use the MMU2 this might not work for you.

But anyway, this was a remarkable innovation from Prusa. Things like this let me hold Josef always in high regards.

So, for the new MKxS extruder they changed the filament sensor completely. They still claim to have an optical sensor, but that is just a light barrier activated by a mechanic. There is a little arm pushed by the filament that then blocks the light in the forked light barrier. And hey, they are not using a spring, they use magnets instead to press the arm out of the fork.

With this new sensor you can still detect if filament is loaded or not, but you cannot monitor if the filament is still moving. So if your nozzle is clogged, that will not be detected anymore.

To me this was a step in the wrong direction. This kind of mechanical sensor is what we have seen before on some Chinese printers. I do understand the pain with the MMU2, but come on, there would have been better ways so solve this.

There are plenty of designs that use a small ball bearing for indirect monitoring of the filament. The sensor then detects the movement of the bearing that is driven by the filament. As the bearing surface and color does not change, there is no problem with the glossy filament or different colors.

That would have been an improvement.

Let's see the MMU2S, what is new? Well, we don't really now. There is no MMU2S branch in Github and the MMU2 branch was not updated for 6 months as of today(Feb 18 2019).

All that was seen in the announcement was a photo of the new "Filament Buffer".

For those who don't know the MMU2. There is a problem when one filament is unloaded from the printer, it gets pushed back. In some cases the filament get interlaced with each other and create problems.

So people come up with solutions like those here:

https://www.thingiverse.com/thing:3241474

https://www.thingiverse.com/thing:3184377

And it seems to me like Prusa did come up with something similar. As the STL´s are not published yet, we cannot confirm. But it also seems like the filament is bended with small radius in there.

Depending on the filament this could lead to break bridle filament in here.

Besides the "upgrades", let's talk about quality.

I used the feather steel build plate with PEI sticker from my original Prusa MK3 kit for about 12 month. I printed PLA, PETG, Nylon and even PC on it. But over time it got some scratches and I even ripped a pice off when I did not wait until it was cooled down when I removed a PETG part.

No big deal, because I ordered already a spare one for 24,99€.

It looked very different from my first one. No raster markings and the little notches on the back have been replaces with a long cavity. I don't care a long as the quality is ok.

And right after the first print, it ripped off a big chunk. I waited for it to cool down, and bended the steel sheet carefully. But Zonk!

Ok, not nice. I expected same quality as my first one, but ok. So I ordered 2 kits of PEI stickers for 9,49€ each to repair both original build plates. I need to admit that I did not read the details, so I was under the impression that I will get 4 stickers, 2 per kit. That made sense to me because if you try to replace one side only, the chances are high you mess up the other side anyway. So usually you would replace the stickers on both sides of the steel sheet.

To my surprise I got 2 stickers in total. So ~10€ for one PEI sticker, both sides is ~20€ then. That raised the question why go thru the hassle to remove the old sticker, clean the surface and apply the new ones with no air bubbles, when you get a complete one for only 5€ more?

I guess I should not have asked the Prusa support, because when I did the price for the complete build plate was raised to 29,99€. Fun fact, as of today, the powder coated version is still advertised with 24,99€. But still not in stock.

I already pointed out in an earlier post that Prusa charges you nearly 60€ for the LCD display plus shipping, that you can buy from Aliexpress for less than 8€, shipping included.

Also some other parts are quite expensive in the Prusa shop. But what is really annoying are the shipping costs. Sometimes the shipping costs rise to a ridiculous amount for small part like springs, nozzles etc. At least I got a 10€ voucher last time when I complained about at the support.

Prusament. Not sure where to start.

Last year I switched my PETG from local German vendors to Prusa because I had very good results with the PETG from Prusa. Also the price was reasonable with just over 20€ per 1Kg spool.

Then Prusa decided to produce their own filament. They advertise a lot with the precision and that you can track any process step by the serial number of the spool.

GREAT! For those people who need this, perfect. But for me this is absolutely irrelevant. I don't care about the process data of my filament spools and for the parts I print the tolerances of the old Prusa Filament was more than ok.

But as this is now made in house, I would guess production costs are cheaper than buying and reselling it from a vendor, right? Well, I don't know. Only thing I can see is that a 1Kg spool costs now 30€. Too much for my taste.

But there is still the option to buy the old filament fron Prusa right? NO

Prusa has removed all old PLA and PETG filament are you find only Prusament now.

Besides the increase in price, they don't even habe all the colors they had before.

Currently I am trying to buy directly from the company that made the filament for Prusa before, which is Plaste Mladic in Czech Republik.

http://www.plastymladec.cz/?id=1

To me all those things add up. The MK3 was not my first printer, I had some cheap chine printers before. They also did the job. But I wanted to support Josef Prusa and thank him for the innovation he brought to the 3D printing community then I decided to buy my MK3 kit and filament for couple hundred €. And honestly I was just think to buy another MK3.

But I am reconsidering this and maybe just build another clone with china parts.

Subscribe to:

Post Comments (Atom)

A new project "automatic cat litter box"

I did not post any updates for a long time. I spent some time making some money with 3D printing to recover some of the costs from this hob...

-

Which is the better printer? Recently I had an argument with Chris Warkocki the admin of the Prusa community group on facebook where he cast...

-

I was thinking of different ways to make the build of the Prusa Firmware easy for everyone. One idea was to build a virtual machine or a doc...

-

I have to admit that was a little frustrated after I could not get the XYZ calibration to work. So this weekend I first wanted to rule out a...

The problem with the sensor change is that he didn't actually try to make an improvement on what the existing tech to get it to work. He was using the sensor wrong to begin with. Only one axis was being measured and they didn't bother to make it so that sensor could not be damaged. They didn't protect the sensor from reverse polarity. There are other VCSELs he could of have used that have both LASER+LED that worK glass surfaces and there was nothing posted about using other sensors. There were already mods that used the sensor the way it was designed to record the movement of the filament using ball bearings that worked just as well as this optical switch he went to. I think it was purely about cost and bad design.

ReplyDeleteHere in germany, you can buy the PM filament at schmelz.bar

ReplyDeleteThe STLs for the Prusa Filament Buffer were added this week.

ReplyDeletehttps://github.com/prusa3d/Original-Prusa-i3/tree/MMU2